High Refractive Index lenses also known by the abbreviation HRI lenses are lenses that are made of a higher density material. The refractive index of lenses refers to the light bending properties of the specific material. The more “dense” the material, the higher the refractive index. This in simple terms means that a higher index lens can bend the light more efficiently without being as thick as a regular index lens. HRI lenses can be as much as 50% thinner than regular lenses. In this way, lens powers can be achieved by less curvature on the lenses, and hence thinner lenses.

For example, Air has a refractive index of 1. And pure water has a refractive index of 1.33, and the densest clear material known to man is a diamond, which has a refractive index of 2.4. the higher refractive index also means the specific material reflects light more, as the light cannot enter it easily due to the increased density of the material, that is why diamonds “sparkle” as they do because they reflect the light more. The Refractive index of Glass ranges from 1.53, to 1.9. The Flint Glass which has the higher refractive index Is heavier than normal glass due to the higher specific gravity of the material. In Plastic, the refractive index ranges from 1.498 (CR-39 plastic) to 1.74 (a specific variety of high-index plastic). So, for the same prescription power and lens design, a lens made of CR-39 plastic will be the thickest lens available, and a 1.9 high-index glass lens will be the thinnest.

The higher index lenses on the downside tend to reflect light more, and for this reason it is essential to treat the surfaces of these lenses with an Anti-reflective coating. The improved aesthetics of HRI lenses far outweighs the fact that they are slightly more expensive than regular index lenses. The higher your prescription, the greater the benefit from HRI lenses. Most of the higher refractive lenses are also not as brittle as regular lenses and are thus ideal for rimless type lens mounting. Your eyecare practitioner will advise you on whether you would benefit from HRI lenses.

Types

The index of refraction (or refractive index) of a spectacle lens material is a number that is a relative measure of how efficiently the material refracts (bends) light, which depends on how fast light travels through the material.

Specifically, the refractive index of a lens material is the ratio of the speed of light in a vacuum, divided by the speed of light in the lens material.

For example, the index of refraction of CR-39 plastic is 1.498, which mean light travels roughly 50 percent slower through CR-39 plastic than it does through a vacuum.

The higher the refractive index of a material, the slower light moves through it, which results in greater bending (refracting) of the light rays. So, the higher the refractive index of a lens material, the less lens material is required to bend light to the same degree as a lens with a lower refractive index.

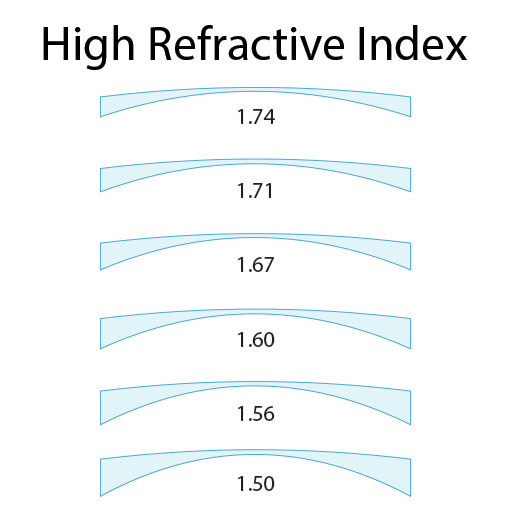

In other words, for a given eyeglass lens power, a lens made of a material with a high refractive index will be thinner than a lens made of a material with a lower refractive index.

The refractive index of current eyeglass lens materials ranges from 1.498 (CR-39 plastic) to 1.74 (a specific variety of high-index plastic). So for the same prescription power and lens design, a lens made of CR-39 plastic will be the thickest lens available, and a 1.74 high-index plastic lens will be the thinnest.

Materials

In the early days of vision correction, all spectacle lenses were made of glass.

Although glass lenses offer exceptional optics, they are heavy and can break easily, potentially causing serious harm to the eye or even loss of an eye. For these reasons, glass lenses are no longer widely used for spectacle lenses. Normal Crown glass lenses have a refractive Index of 1.532

In 1947, the Armorlite Lens Company in California introduced the first lightweight plastic eyeglass lenses. The lenses were made of a plastic polymer called CR-39, an abbreviation for "Columbia Resin 39," because it was the 39th formulation of a thermal-cured plastic developed by PPG Industries in the early 1940s.The refractive Index of this material is 1.49, which renders it a little thicker than glass or Polycarbonate. Because of its light weight (about half the weight of glass), low cost and excellent optical qualities, CR-39 plastic remains a popular material for eyeglass lenses even today.

In the early 1970s, Gentex Corporation introduced the first polycarbonate lenses for safety glasses. Later that decade and in the 1980s, polycarbonate lenses became increasing popular and remain so today. Polycarbonate material has a refractive index of 1.61. It was originally developed for helmet visors for the Air Force, for "bulletproof glass" for banks and other safety applications, polycarbonate is lighter and significantly more impact-resistant than CR-39 plastic, making it a preferred material for children's eyewear, safety glasses and sports eyewear.

A newer lightweight eyeglass lens material with similar impact-resistant properties as polycarbonate is called Trivex (PPG Industries), which was introduced for eyewear in 2001. Trivex material typically has a refractive index of 1.56.

In the past 20 years, in response to the demand for thinner, lighter spectacle lenses, a number of lens manufacturers have introduced high-index plastic lenses. These lenses are thinner and lighter than CR-39 plastic lenses because they have a higher index of refraction (see below) and may also have a lower specific gravity.

Lens Thickness

The FDA has guidelines for impact resistance, so there's a limit to how thin an optical laboratory can grind your lenses.

In (concave) lenses for the correction of myopia, the thinnest portion of the lens is the optical center, located at or near the middle. In (convex) lenses that correct farsightedness, the thinnest portion of the lens is at its edges.

Because of their superior impact resistance, polycarbonate and Trivex lenses that correct myopia can be fabricated to a center thickness of just 1.0 mm and still pass the FDA impact-resistance standard. Myopia-correcting lenses made of other materials usually have to be thicker in the center to pass the standard.

The size and shape of your eyeglass frames also will affect the thickness of your lenses, especially if you have a strong prescription. For thinner lenses, choose smaller, round or oval frames. Also, plastic frames hide edge thickness better.. Choosing the right combination of frame and lens material is important to both your appearance and your comfort when wearing spectacles. The lenses you choose influence four factors, namely, appearance, comfort, vision and safety.

Generally, the thinnest lenses for your prescription will be aspheric lenses made of a high-index material, worn in a small frame.